Light Box

CAD, Kicad, PCB milling, and integration design sprint for medical device capstone

- Category: Product Design

- Client: Duke Medical Device Design

- Project date: 08/2021 - 12/2021

- Project Report: View

Contributions & Outcomes

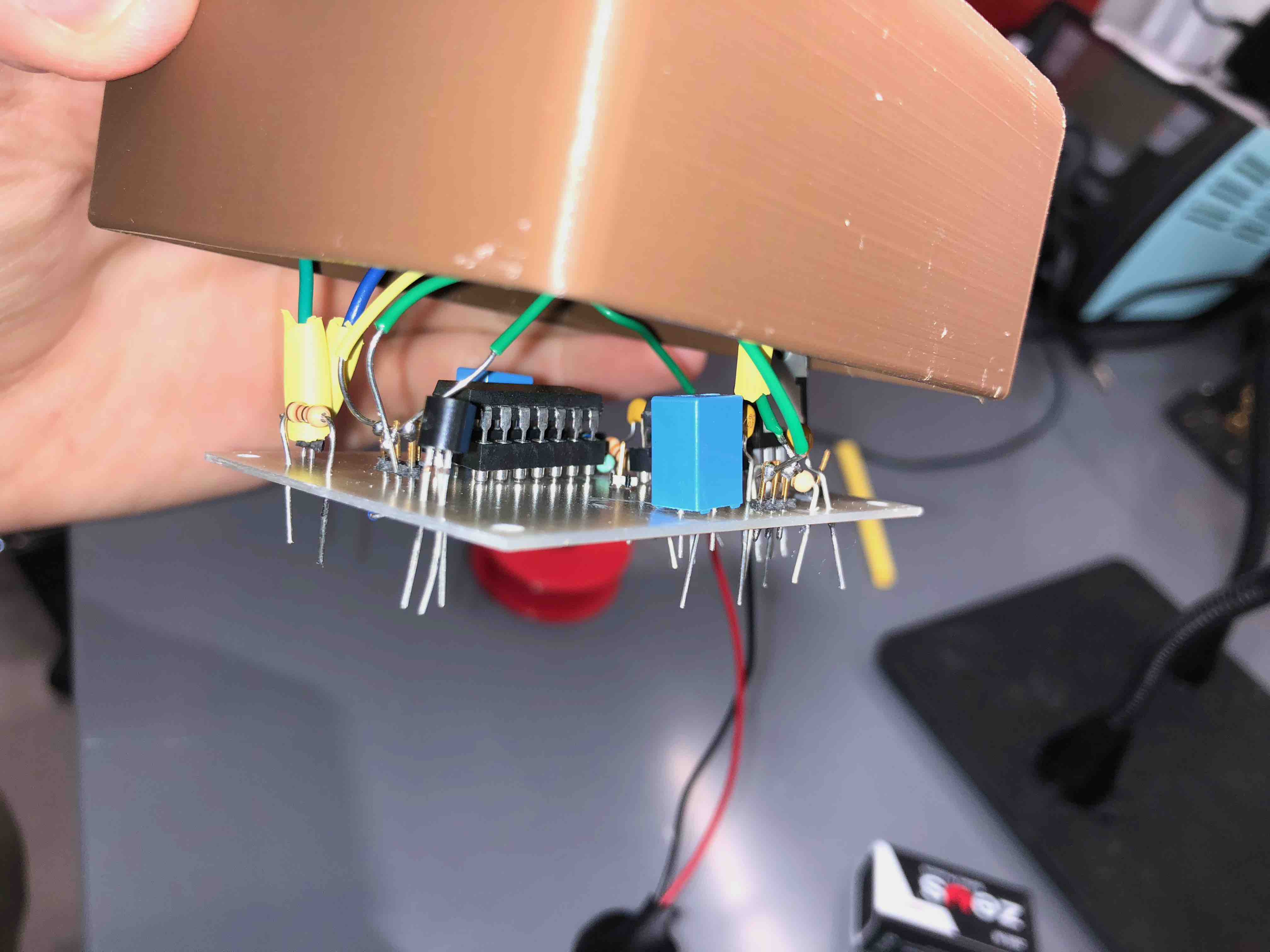

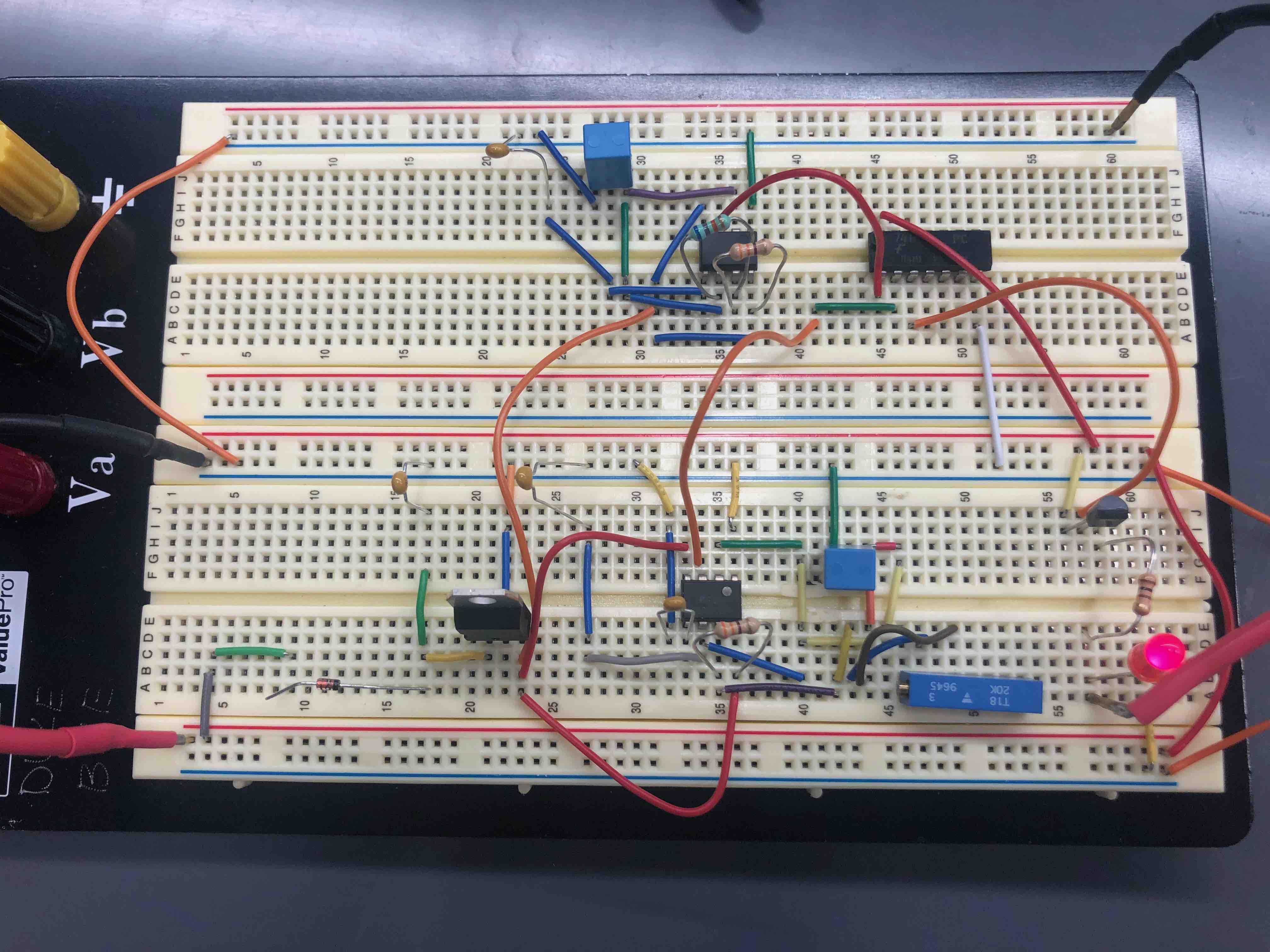

The project involved the design and development of a CAD enclosure for a light box, which was intended to seamlessly integrate with a printed circuit board (PCB). The PCB featured a voltage-regulated circuit with inverse polarity protection, specifically designed to illuminate an LED. To achieve adjustable brightness of the LED, a 555 timer was incorporated into the circuit design. For comprehensive details, including CAD drawings, circuit schematics, 3D PCB renders, and videos showcasing the final product, please refer to the provided website link.

Technical Skills

- Design Thinking

- CAD

- Mechatronics

- Circuit Schematic Design

- PCB Design & Milling

- Soldering

- Oscilloscope Debugging

.jpg)